Nitrex: protection foam

EVA-GLORY Industrial Co., Ltd

Nitrex: protection foam

EVA-GLORY Industrial Co., Ltd

Back to Innovators

Back to Innovators

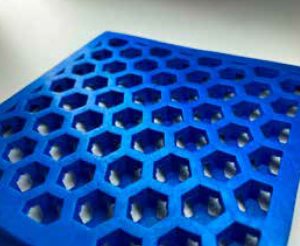

Nitrex is a shock absorption foam and impact absorbing

foam material widely used in sports, motorcycle, industrial

and military protection, its closed-cell structure making it

waterproof, sweat-resistant and to prevent any moisture

absorption.

Nitrex is closed-cell foam, whereas PU is open-cell and

is only waterproof on its surface. Once the surface is

cracked, PU loses its waterproof function. PU foam is often

replaced after a certain period of usage because it is prone

to hydrolysis. In contrast, Nitrex, has excellent weather

resistance and durability, so Nitrex has longer service life

than PU foam, helping to reduce the amount of waste and

further reduce environmental pollution.

Nitrex can be cut and stitch like fabrics, as well as 3D

molded parts thermo moldable to fit the ergonomics design

for protector’s ease of movement and flexibility so that

Nitrex used in body protection can exceed the performance

requirements of EN1621 for motorcycle and winter sports,

EN13158 for Equestrian, EN1077/1078, NOCSAE for helmets

protection, and many other standards.

Highlights

- Nitrex has excellent durability: It not only reduces waste generated during processing but also protects the environment.

- Staying safe: Nitrex will be tested by our in-house impact laboratory and the third international certification before shipment.

- Combined with the recycling concept, Nitrex could add recycled foam materials. It is more unique and irreplaceable than other foam materials.

- EVA GLORY can produce Nitrex through injection technology to control the waste generated under 5%. Foam injection technology is safer and simple to operate, so Nitrex can greatly increase job opportunities.

The best choice to protect foam: Nitrex

View Website

Back to Innovators

Back to Innovators

Nitrex is a shock absorption foam and impact absorbing

foam material widely used in sports, motorcycle, industrial

and military protection, its closed-cell structure making it

waterproof, sweat-resistant and to prevent any moisture

absorption.

Nitrex is closed-cell foam, whereas PU is open-cell and

is only waterproof on its surface. Once the surface is

cracked, PU loses its waterproof function. PU foam is often

replaced after a certain period of usage because it is prone

to hydrolysis. In contrast, Nitrex, has excellent weather

resistance and durability, so Nitrex has longer service life

than PU foam, helping to reduce the amount of waste and

further reduce environmental pollution.

Nitrex can be cut and stitch like fabrics, as well as 3D

molded parts thermo moldable to fit the ergonomics design

for protector’s ease of movement and flexibility so that

Nitrex used in body protection can exceed the performance

requirements of EN1621 for motorcycle and winter sports,

EN13158 for Equestrian, EN1077/1078, NOCSAE for helmets

protection, and many other standards.

Highlights

- Nitrex has excellent durability: It not only reduces waste generated during processing but also protects the environment.

- Staying safe: Nitrex will be tested by our in-house impact laboratory and the third international certification before shipment.

- Combined with the recycling concept, Nitrex could add recycled foam materials. It is more unique and irreplaceable than other foam materials.

- EVA GLORY can produce Nitrex through injection technology to control the waste generated under 5%. Foam injection technology is safer and simple to operate, so Nitrex can greatly increase job opportunities.

The best choice to protect foam: Nitrex